BTA Deep Hole Drilling Machine

Product Introduction

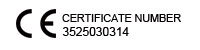

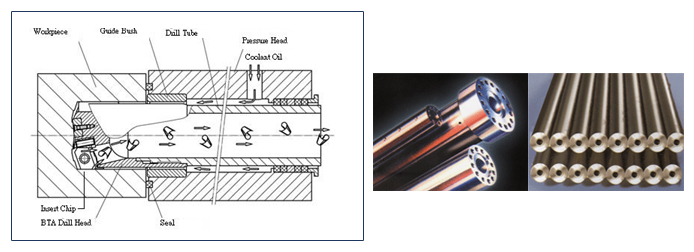

BTA deep hole drilling machines are specialized machines designed for large-diameter deep hole drilling and deep hole machining. BTA machines can create extremely deep and precise holes in a wide range of materials. Microdrilling BTA deep hole drilling machines integrate advanced technologies, including tool support, coolant pressure, and machine power, to precisely and efficiently handle deep hole drilling applications.

The BTA deep hole drilling machine series offers two options: the WR type and the TR type. The configuration is usually based on the size and shape of the workpiece, desired production rate, and accuracy specifications. During the drilling process, the chips are flushed out through the center of the BTA tool and then discharged through the drill tube and machine spindle, eliminating the need for interrupted feed or segmented drilling to remove chips. This greatly improves production efficiency.

Model: WR-120 x 3000 (Workpiece rotation)

Model: TR-80 x 1800 (Drill head rotation)

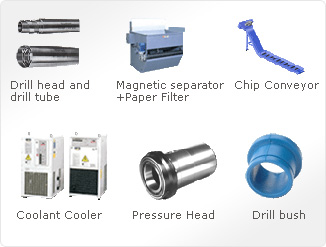

Special Accessories

- Machines utilizing the BTA Deep Hole Drilling System for solid deep hole boring 30 – 200mm in diameter.

- Deep hole drilling machine's drilling depths up to 5000mm.

- Coolant filtration to 30 microns.

- The rigid honeycomb walled Bed gives a stable cutting condition. FC-32 castings have been stress relived and annealed.

- Hardened and ground ways to hardness HRC 60. The opposite ways and gibs are all Turcite-B plated with hand-scraped bearing surfaces.

- An automatic lubrication pump is provided as a standard accessory to ensure all the bearing surfaces and screws are well-lubricated.

- All box-way design provides rigidity for heavy cutting.

- Type WR is the workpiece rotation. TR is the drilling head rotation, the workpiece is fixed on the fixture.

- CE marks are available for special requirements.

| Specification | Model No. | TR-80 | TR-120 | WR-80 | WR-120 | WR-200 |

|---|---|---|---|---|---|---|

| Drill Capacity | Hole dia | Ø30~Ø80mm | Ø30~Ø120mm | Ø30~Ø80mm | Ø30~Ø120mm | Ø30~Ø200mm |

| Max. depth (Z) | 1000/2000 mm |

1000/2000 mm |

1000/2000 /3000mm |

2000/3000 /4000mm |

2000/3000/4000 /5000mm/6000mm |

|

| Power | Spindle motor | 50 kw with Inverter | 75 kw with Inverter |

30 kw with Inverter |

50 kw with Inverter |

75 kw with Inverter |

| Drill spindle feed (Z) | Servo motor 850~1300W / 5.39~8.34 N.M.. | 4.0 kw | 7.0 kw | 11.0 kw | ||

| High pressure pump motor | - | |||||

| Speed | Max. spindle speed | 150~1500 rpm | 120~1200 rpm | 150~1500 rpm | 150~1500 rpm | 120~1200 rpm |

| Drill Speed | 1~200 mm/min | |||||

| Rapid | 4000 mm/min | |||||

| Ball screw for feeds Z-Axis | Ø63 x P10 | Ø80 x P10 | Ø63 x P10 x C5 | Ø80 x P10 x C5 | ||

| Swing over bed | 500 mm | 770 mm | 500 mm | 770 mm | ||

| Controller | FANUC / MITSUBISHI / SIEMENS / SYNTEC | |||||

| High pressure pump (Every spindle one set) |

Pump output | 350 Liter/ min | 1000 Liter/ min | 350 Liter/ min | 750 Liter/ min | 1000 Liter/ min |

| Max. pressure | 25 kgs/cm2 | |||||

| Coolant tank | 1600 L | 4500 L | 1600 L | 4500 L | 6000 L | |

| Floor space | - | |||||

| Standard accessories |

|

|||||

| Optional accessories | Coolant tower Model:

|

|||||